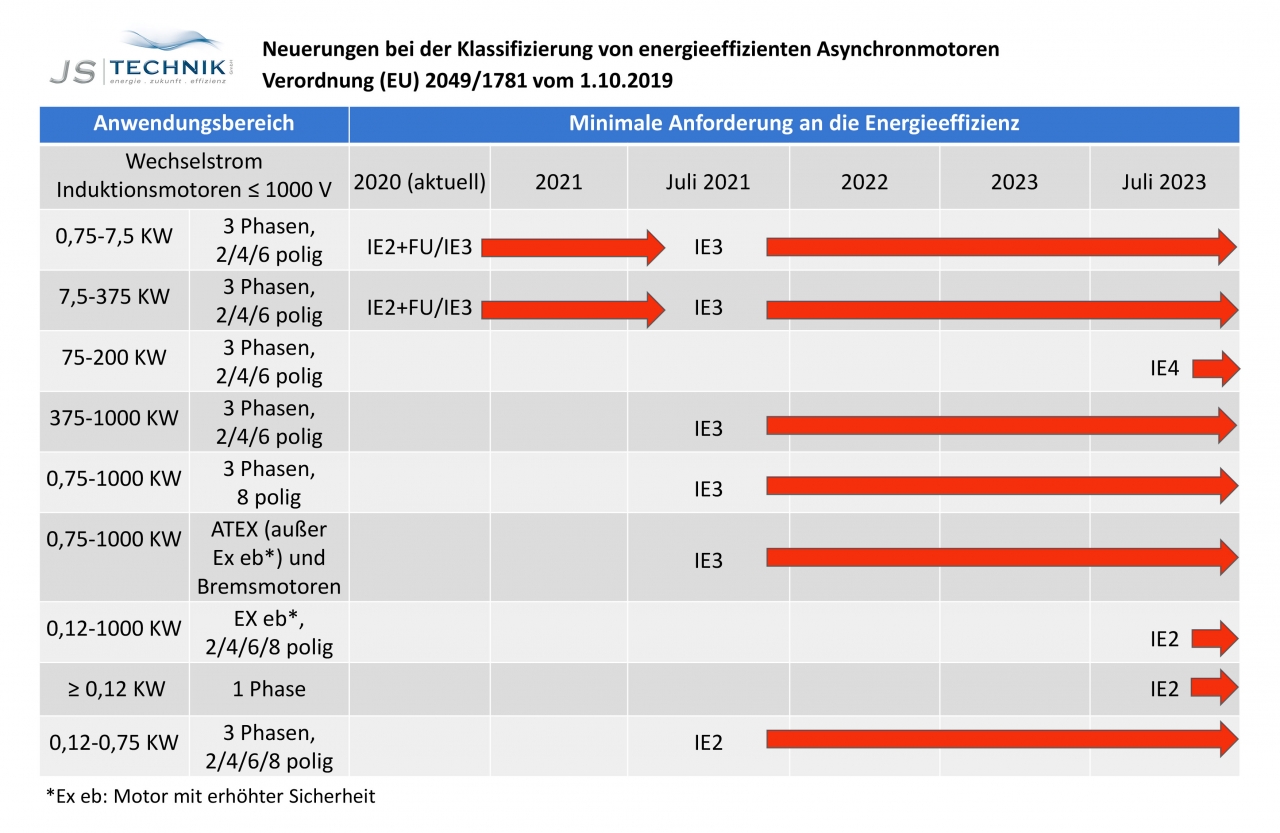

New regulation of efficiency classes for asynchronous motors

here you will find the current efficiency levels - new regulations for electric motors. The required efficiency specifications are of course available from JS-Technik.

Electric drive as special design

In many cases, electric motors are also required as special designs with customised requirements. We are the ideal partner for you here, as our specialist staff, combined with our extensive motor warehouse and in-house final assembly, enable us to cover a wide range: special brake motors, circular saw motors, electric motors with frequency inverters, drum motors, special shafts, standstill heaters, special voltages or as electric motors with a rotary encoder for setpoint/actual value adjustment.

Shaft heights and power ranges of the motors

Here you will find a selection of electric motors in aluminium design in sizes 56, 63, 71, 80, 90, 100, 112 and132, with an output of 0.06kW, 0.09kW, 0.12kW, 0.25kW, 0.37kW, 0.55kW, 0.75kW, 1.1kW, 1.5kW, 2.2kW, 3.0kW, 4.0kW, 5.5kW and 7.5kW. If required, we can of course also supply progressive motors of reduced size. Our drives are available in various speeds, i.e. 2-pole, 4-pole, 6-pole and 8-pole. The terminal box position is at the top as standard, but can be varied thanks to the removable feet. Our IEC standard motors are generally suitable for use with frequency inverters and are therefore infinitely variable.

Progressive motors

Progressive three-phase motors are electric motors with increased power in a smaller housing. In confined environments where a normal electric motor does not have enough space, the progressive design is a sensible solution. Progressive or high-output electric motors are also frequently used in hydraulic pumps. We are happy to offer you progressive motors on request.

Operating modes of three-phase motors

JS-Technik drives are available in the following operating modes: Continuous operation S1, short-time operation S2, intermittent operation S3 (without starting, without braking), intermittent operation S4 (with starting, without braking), intermittent operation S5 (with starting, with braking), continuous operation S6 (with intermittent load), reversing operation S7, continuous operation (with variable speed).

Design and terminal boxes

The design of the JS motors is variable on request. The feet of the motor can also be converted for the AC motors in the light version, i.e. from 0.12 kW to 7.5 kW. This means that a foot motor B3 can also be converted into a flange motor B5 or a foot/flange/motor B3/B5. Another advantage is that the electric drive can be converted into a terminal box position in KK-upper, KK-left, KK-right, even KK-bottom.

Electrical connection of electric motors

All work may only be carried out by qualified specialist personnel on the stationary electric motor when it is disconnected and secured against being switched on again. This also applies to auxiliary circuits (e.g. standstill heating, brake, forced cooling fan, etc.). Check that there is no voltage!

sEO=New regulation of efficiency classes for asynchronous motors - Buy electric motors cheap !